Robots are the cells and tissues of the automotive industry

The automotive industry is the fastest growing and developing industry when compared to other fields. We can also call the automobile industry the largest user of robotic applications. The use of robots in every part makes the industry highly automated in the world of supply chains.

As previously said the automotive industry has lots and lots of raw materials to deal with while manufacturing a vehicle. It is difficult to process all parts inside a car without any robotic help. The automotive manufacturing industries use robots from painting the vehicle to fitting a tire making them the powerhouse of the industry.

Some paramount applications of using robots in the automotive industry

1. Collaborative robots

The ordinary robots need manual programming for every task they commit while the collaborative robots are the combination of artificial intelligence with robotics. The collaborative robots can guide other robots to complete their tasks effectively to run a smooth process of vehicle production. The collaborative robots can command the robots for welding, painting, and any other tasks to optimize and help to release the stress of the workers in the manufacturing environment.

One can trust the robots even with the professional tasks

The robots can now work as professionals in the automotive culture. As the demand for professional painter is scarce it becomes necessary for the automobile industries to fetch help from the robots to minimize their material and maximize their savings in the paint of vehicles.

The next thing is interesting to watch out for robotic applications. The automotive industries are using robots for welding the vehicle parts. This can increase the speed of their production rate while managing a high amount of welding efforts with maintaining quality and the best standards.

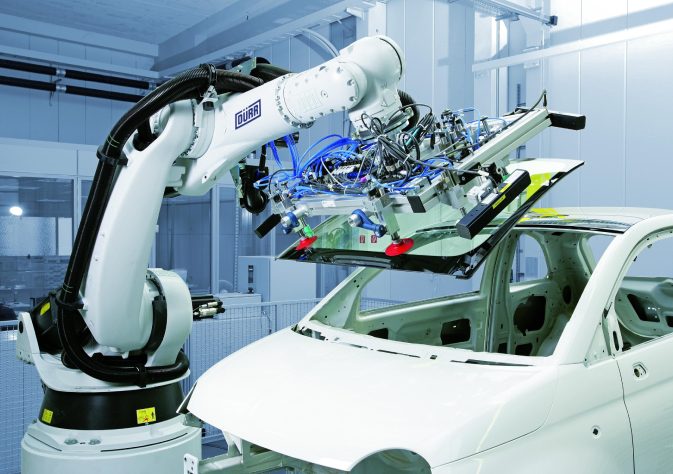

The robots can also work efficiently at the assembly line providing improved services of the motor and pumps and also while installing windshields and small plastic components.

The robots also work in the cutting and trimming lines to save as much as fabric they can and installing plastic molds and casting them into finished products.

The hazardous activities to human health can now be transferred to the robots. Installation of machines, loading, and unloading of heavy machines and hot liquids can cause injuries to a human so it is compulsory for man to fetch help from robots.